scale up of power consumption in agitated ball mills

Scale‐up of power consumption in agitated ball mills

Previous investigations have shown that the specific energy input is the overall parameter of influence on product size during communition in agitated ball mills, from laboratory up to industrial scale. The specific energy input is the introduced energy related to the amount

Scale‐up of power consumption in agitated ball mills 百

2010年5月17日 Mathematical models are presented which describe the power consumption in agitated ball mills in absence of grinding beads. In addition, tests with

A DEM based scale-up model for tumbling ball mills

2022年9月1日 A scale-up model was developed based on data of DEM simulation to quickly predict ball milling performance for different mill design and operation

Scale‐up of power consumption in agitated ball mills

Scale‐up of power consumption in agitated ball mills. Herbert Weit, J. Schwedes. Published 1987. Engineering. Chemical EngineeringTechnology. Des essais experimentaux en

(PDF) Empirical and scale-up modeling in stirred

2011年4月1日 The power consumption of the stirred ball mill for scale-up was determined by a method based on the dimensional analysis. A new

Breaking down energy consumption in

2017年1月17日 The grinding process in ball mills is notoriously known to be highly inefficient: only 1 to 2% of the inputted electrical energy serves for creating new surfaces. Scale-up of mills is critical

sbm/sbm scale up of power nsumption in agitated ball

Contribute to dihog/sbm development by creating an account on GitHub.

MODELING THE SPECIFIC GRINDING ENERGY AND BALL

2021年2月24日 21 CONCLUSIONS Continued In the present work, equations were also derived, giving: zthe ball-mill power drawP as a function of its dimensions: internal mill

Github

scale up of power consumption in agitated ball mills power consumption of ball mill agitated ball mill How To Reduce Power Consumption For Ball Mills Accurate Scale Up IsaMill

scale up of power consumption in agitated ball mills

Scale-up of power consumption in agitated ball mills Previous investigations have shown that the specific energy input is Previous investigations have shown that the

Power consumption of stirred media mills SpringerLink

1995年2月1日 A procedure for estimating the parameters of effective viscosity and scale-up guidelines (with respect to power consumption) are proposed. 1987, “Scale-up of power consumption in agitated ball mills,” Chemical Engineering Technology, Vol. 10, pp. 398–404. Article Google Scholar Wills, B.A., 1992, Mineral Processing Technology, 5th

sbm/sbm scale up of power nsumption in agitated ball

Contribute to dihog/sbm development by creating an account on GitHub.

MODELING THE SPECIFIC GRINDING ENERGY AND BALL

2021年2月24日 21 CONCLUSIONS Continued In the present work, equations were also derived, giving: zthe ball-mill power drawP as a function of its dimensions: internal mill diameter D and length L, zthe ball-mill power drawP as a function of the feed D f (mm) and the product size d (mm), the Bond work index w i (kWh/short ton) and the mill throughput

Ball Mill Design/Power Calculation Mineral

2015年6月19日 If P is less than 80% passing 70 microns, power consumption will be; Ball Mill Power Calculation Example #1. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work

Planetary Ball Mills 101 Union Process

In comparison, internally agitated high energy ball mills, such as a batch process Attritor, scale up easily and efficiently to large production machines capable of processing hundreds of gallons per batch. Attritors also can run in continuous mode, which is another advantage over planetary mills, which cannot run in continuous mode.

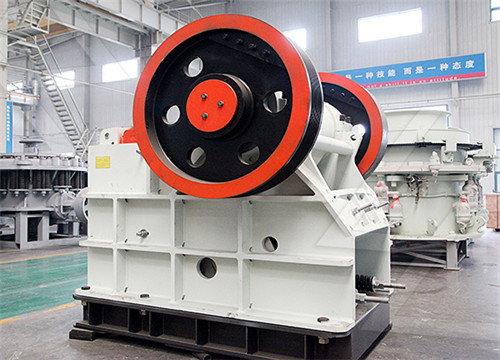

Agitated Ball Mill Crusher Mills, Cone Crusher, Jaw Crushers

Scale-up of power consumption in agitated ball mills Weit Previous investigations have shown that the specific energy input is the overall parameter of influence on product size during communition in agitated ball mills

scale up of power consumption in agitated ball mills

Scale‐up of power consumption in agitated ball millsPrevious investigations have shown that the specific energy input is the overall parameter of influence on p +0086 371 169 Science Avenue, High-tech Zone, Zhengzhou, China

scale up of power consumption in agitated ball mills

Scale-up of power consumption in agitated ball mills Previous investigations have shown that the specific energy input is Previous investigations have shown that the specific energy input is the overall parameter of influence on product size during communition in agitated ball mills

ball mill specific consumption

Scale‐up of power consumption in agitated ball mills . Previous investigations have shown that the specific energy input is the overall parameter of influence on product size during communition in agitated ball mills from laboratory up to industrial scale The specific energy input is the introduced energy related to the amount of comminuted material This

Scale Up Of Power Consumption In Agitated Ball Mills, Ball

2020年6月1日 Agitated Ball Mill Calculation. Grinder mill applications you may be interested in design of agitated media mill for dry grinding ball mill motor sizing calculation example a 7 ft diameter dry grinding diaphragm mill has a 40 percent ball charge and a speed of 236 rpm what is the horsepower per foot of length the mill has 2 in thick shell

Effects of Ball Size Distribution and Mill Speed and Their

2020年7月2日 In total, 165 scenarios were simulated. When the mills charge comprising 60% of small balls and 40% of big balls, mill speed has the greatest influence on power consumption. When the mill charge is more homogeneous size, the effect of ball segregation is less and so the power consumption of the mill will be less affected.

sbm/sbm scale up of power nsumption in agitated ball

Contribute to dihog/sbm development by creating an account on GitHub.

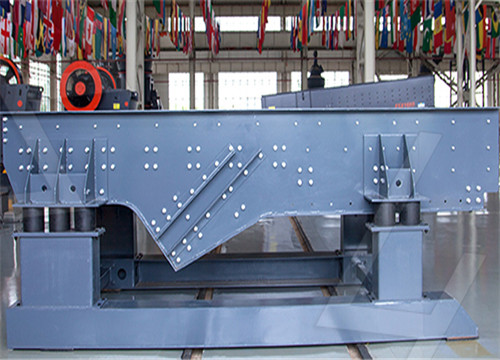

Scalability of Agitated Bead Mills 2014-04-01

2014年5月1日 Scale up of agitated bead mills is possible. The scale up method is based on the product and the mill type used. where P is the total power consumption of the mill; P 0 is the idle power (power

Estimating Ball Consumption Molycop

where dr represents the diameter of the new make-up balls periodically charged to the mill. In an attempt to further improve the accuracy of the new correlation, additional variables such as mill diameter, speed (as a % of critical velocity) and product size (P80) were also considered and tested without significant improvement.

Ball MillsAgitated Media Mills Hosokawa Alpine

Overview of our ball mills and agitated media mills. The classic ball mill Super Orion S.O. is suitable for dry hard crushing and achieves finenesses of under 10 µm. For superfine dry grinding: The energy-efficient Pulvis combines a vertical agitator bead mill with a high-performance classifier and is also suitable for grinding hard materials

scale up of power consumption in agitated ball mills

Scale‐up of power consumption in agitated ball millsPrevious investigations have shown that the specific energy input is the overall parameter of influence on p +0086 371 169 Science Avenue, High-tech Zone, Zhengzhou, China

Solids and powder milling Size reduction

2022年7月31日 The mechanical action used to break the particles and reduce the size can be diverse and different mill exist that will use the milling principles. Typical milling principles are the following : Use of 2 solid

Scale Up Of Power Consumption In Agitated Ball Mills

Grinding media (steel balls) on power requirements and energy consumption of a ball mill.with constant mass of the steel balls (20, 30 and 40 kg), the agitator shaft speed was increased from 10 to 100% of the maximum speed, which corresponds to a speed of 50 rpm.the power consumption (w) was recorded upon which milling energy consumption.

power consumption in ball mill aubergedesrives.fr

Ball Mill Design/Power Calculation. Jun 19, 2015 If P is less than 80% passing 70 microns, power consumption will be Ball Mill Power Calculation Example #1 A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns).

scale up of power nsumption in agitated ball mills

Scale Up Of Power Consumption In Agitated . May 01, 2022 Scale up of agitated bead mills is possible. Sometimes, especially in the case of minimized lab equipment, a twostep scale up is necessary. The scale up method is based on the product and the mill type used.