graphite processing equipment

A Comprehensive Guide to Graphite Processing Equipment

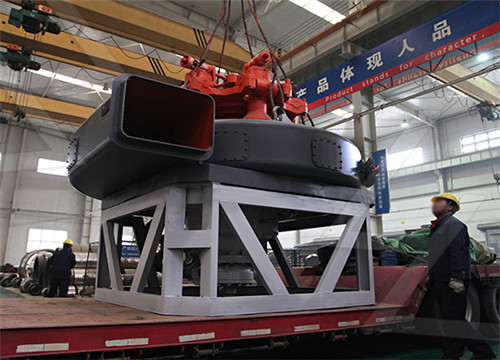

2023年1月16日 Graphite vertical stirring mill has the comprehensive features of the tower mill, stripping machine, and sand mill, which can effectively grind the material to 10um or

Graphite

Spherical graphite grinding system: The spheroidization process is the most important step for making cathodeanode materials. Prominer has the

Graphite Processing Equipment, Process Flow,

2019年8月23日 Description. Pure graphite is a mineral form of the element carbon (element #6, symbol C). It forms as veins and disseminations in metamorphic rocks as the result of the metamorphism of organic material

7 Common Graphite Processing Methods Xinhai Xinhai

01Graphite Flotation Method02Graphite Gravity Separation Method03Graphite Electric Separation Method04Graphite Selective Flocculation Method05Graphite Alkaline Acid Method06Graphite Chlorination Roasting Method07Graphite High Temperature Roasting Method

Graphite has good natural floatability and hydrophobicity. Therefore, most graphite processing plants use the flotation method to purify graphite ore, that is, adding a series of flotation reagents to enrich the graphite ore in the gas-liquid interface to achieve separation from impurity minerals. Therefore, most concentrators use the flotation met...

Optimal Graphite Ore Processing Making the Most of

2023年2月15日 Graphite ore crushing. (1) Raw ore feeding particle size: 300~500mm; (2) Final product particle size: 10~20mm; (3) The commonly used crushing process is a two

Graphite mineral processing flowsheet Yantai

Graphite beneficiation method include flotation, electrostatic separation, gravity separation, etc. Flotation is the most widely used process. Graphite mineral processing are mainly suitable for all kinds of graphite with

Graphite Plant International Graphite Operations

Downstream Graphite Processing at Collie. A new pilot scale processing facility, including graphite micronising and spheroidising equipment, has been successfully commissioned

What Are Graphite Processing Equipment and How to

2016年4月21日 The filter equipment of graphite is mainly the disc vacuum filter which covers small areas, has simple operation and good filter effect and large filter area.

5 Stages of Graphite Processing Mining Pedia

2021年6月11日 The process of graphite beneficiation is mainly: crushing-grinding-separation-middling treatment-tailings treatment. 1. Crushing. The hardness of graphite

Graphite in the Production of Semiconductors SGL Carbon

High-purity graphite components are crucial to processes in the semiconductor, LED and solar industry. Our offering ranges from graphite consumables for crystal growing hot zones (heaters, crucible susceptors, insulation), to high-precision graphite components for wafer processing equipment, such as silicon carbide coated graphite susceptors for Epitaxy or

Industrial Carbon and Graphite Materials: Raw Materials

2022年6月19日 6.5.6.4.1 The Process of Self-Baking Electrodes 328 References 329 6.5.7 Graphite Process Equipment 331 Marcus Franz 6.5.7.1 Heat Exchangers 332 6.5.7.2 Absorbers, Desorbers, and Distillation Columns 335 6.5.7.3 Hydrochloric Acid and

Carbon Graphites Schunk Carbon Technology

Carbon Graphite. With Schunk at your side, you can rely on "high-performance materials" also for carbon graphite. Our international customers benefit not only from our high-quality solutions, but also from our application technology consulting and our product diversity. In the Mechanical Carbon sector, Schunk carbon graphite materials are

Graphite mineral processing flowsheet Yantai

Graphite beneficiation method include flotation, electrostatic separation, gravity separation, etc. Flotation is the most widely used process. Graphite mineral processing are mainly suitable for all kinds of graphite with

7 Common Graphite Processing Methods Xinhai Xinhai

2022年3月22日 Graphite ore is an important non-metallic mineral resource, which can only be used after processing. Common graphite processing methods mainly include flotation method, gravity separation method, electric separation method, selective flocculation method, alkali-acid method, chlorination roasting method and high temperature roasting

Major Graphite Research Project Aims To Reshape

2023年4月13日 Ramaco will be in charge of a number of tasks, such as using specialized machinery at its iCAM research facility in Wyoming to prepare feedstocks for the process using coal from the mines of its

How to Extract Graphite? 7 Graphite Processing Methods

2022年11月29日 The flotation process of flake graphite ore mostly adopts multi-stage grinding, multiple separation, coarse concentrate re-grinding, and then separation process flow to protect the flake. Graphite flotation separation can beneficiate the graphite grade reaching 80%~90% or even to almost 95%. And the method has been found to feature

Graphite Grinding Machine Powder Mill Equipment mpl

2021年10月26日 Graphite grinding machine mainly includes ultrafine grinding mills, vertical roller mills, high-pressure mills, ring roller mills, and so on. They can grind non-metallic ores including graphite into fine powders, with the highest fineness up to 3000 mesh. The fineness can be adjusted freely, and it can be equipped with a secondary powder

Spherical graphite processing method and equipment

2007年9月18日 The invention provides a spherical graphite processing method and an equipment system. The method comprises the steps as follows: (1) spheroidizing: the graphite material with D50 equivalent to 50micron plus or minus 5micron is spheroidized in an efficient grinder which is added with a prilling medium; and (2) multiple classification:

Graphite Keller USA

The processing of graphite materials by turning, milling, drilling or grinding during metalworking generates fine dust inside the work area. This dust can permeate machinery, the workplace, and the surrounding environment. High efficiency dust separation systems are required to prevent potential health risks and to adhere to regulatory

Graphite Processing Equipment, Process Flow,

2019年8月23日 Description. Pure graphite is a mineral form of the element carbon (element #6, symbol C). It forms as veins and disseminations in metamorphic rocks as the result of the metamorphism of organic material

Graphite, Graphite Mining, Graphite Ore

Graphite Ore Mining Production Line. [Introduction]: The graphite mining processes are mainly the gravity separation process, froth flotation process, electric separation process, and the combination process. And froth

Graphex Group, a Global Supplier of Graphite, Announces

2022年2月7日 Graphex, a global leader in the industry, has been proficient in commercial graphite processing since 2013 and is currently producing over 10,000 metric tons of spherical graphite annually. Its

Graphex Group Announces Expansion Plans for its

2022年2月15日 Graphex is a global leader in the industry and has been proficient in graphite processing in Jixi since 2008 and transacting commercially since 2013. The Company’s senior executives include

Graphite mineral processing flowsheet Yantai

Graphite beneficiation method include flotation, electrostatic separation, gravity separation, etc. Flotation is the most widely used process. Graphite mineral processing are mainly suitable for all kinds of graphite with

Graphite Ore Processing Mineral Processing

The graphite flotation process is widely used, mainly including multi-stage grinding, gravity-flotation combined process, and selection of mineral processing equipment. Inquiry Now. Graphite beneficiation process. Graphite ore is divided into earthy graphite ore and flake graphite ore. Natural flake graphite collected from natural mines often

Study on production technology of spherical graphite

2020年5月6日 Secondly, regarding the choice of spherical graphite processing equipment. (1) The air flow vortex crusher is widely used in the spherical process, which has both the crushing performance and the effect of chamfering. In addition, the quality of the grading equipment will directly affect the yield of spheroidized graphite and the control of the

Graphite ore flotation processing flow chart

This graphite ore flotation plant including: (1) Preparation processing: first and second crushing, and coarse milling. (2) Flotation processing: rough separating, sweeping separating and fine separating. (3) Concentrates

Graphite AMECA Mining

Graphite is a naturally occurring form of crystalline carbon. It is a native element mineral found in metamorphic and igneous rocks. Graphite is a mineral of extremes. It is extremely soft, cleaves with light pressure, and has a very low specific gravity. In contrast, it is extremely resistant to heat and nearly inert in contact with almost any

How to Extract Graphite for Different Types? Mining-pedia

2019年12月24日 Flake Graphite Processing. For the flake graphite ore, because of the higher, the purity is and the larger the flake is, the function and price are higher. Therefore, in the flake graphite mining process, it is important to adopt various measures to increase the large flake productivity and the graphite grade. The traditional flake graphite