Cement raw meal drying and crushing

Analysis of material flow and consumption in cement

2016年1月20日 The preparation of raw material involves primary and secondary crushing of the quarried material, drying of the material, further raw grinding, and blending of the material. However, these waste gases from raw meal and cement grinding system at a

From raw materials Extracting raw materials Raw

2022年2月12日 The desired raw mix of crushed raw material and the additional components required for the type of cement, e.g. silica sand and iron ore, is prepared

The Cement Manufacturing Process Advancing Mining

2015年8月20日 Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw

Cement Raw MealHomogenization Process in The

What Is Cement Raw MealRaw Meal HomogenizationHow Does Homogenization WorkThe Development of Raw Meal HomogenizationAgico Raw Meal Equipment

Cement raw meal is the raw material for producing cement clinker, which is prepared in a certain proportion after crushing and grinding. After being calcined in a rotary kiln, the raw meal is turned into the clinker. The composition and shape of the raw meal may vary according to different cement production methods. For ex在cementplantsupplier上查看更多信息

Cement Production Process AGICO

2020年8月25日 There are three steps of the high-temperature system: Drying or preheating, calcining, and sintering. The calcining is the core part of the clinker

Manufacturing process

1 Step 1: Mining. The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a

Raw Material Drying-Grinding Cement Plant Optimization

Drying of moisture in raw materials is required for effective grinding and subsequent handling of raw meal. This is achieved normally by ducting part of the kiln exhaust gas

What is dry cement raw meal grinding mill equipment?

2022年8月25日 2. Introduction of dry cement raw meal grinding mill equipment. Grinding mill equipment is a mechanical equipment used to grind large particle materials into fine

Dry Process Of Cement Manufacturing Dry Cement AGICO

After that, the raw meal will be completely calcinated into cement clinker in the cement kiln by high-temperature heating. Cement Kilns Manufactured By AGICO Cement kiln: the

manufacture of cement using drying process ZWMAJH

2022年8月4日 Dry Process Of Cement Manufacturing\\Dry Process Of 2019-10-29 Dry process method means manufacturing raw materials into raw materials powder, whose

How Cement Is Made Heidelberg Materials

2023年4月10日 The desired raw mix of crushed raw material and the additional components required for the type of cement, e.g. silica sand and iron ore, is prepared using metering devices. Roller grinding mills and ball mills grind the mixture to a fine powder at the same time as drying it, before it is conveyed to the raw meal silos for further

From raw materials Extracting raw materials Raw

2022年2月12日 The desired raw mix of crushed raw material and the additional components required for the type of cement, e.g. silica sand and iron ore, is prepared using metering devices. Roller grinding mills and ball mills grind the mixture to a fine powder at the same time as drying it, before it is conveyed to the raw meal silos for further

A Review on Pyroprocessing Techniques for

2020年2月9日 Vertical roller mills (VRMs) with integrated classifiers have been used successfully for many years in cement plants to grind and dry raw materials simultaneously with moisture contents up to 20% by weight.

(PDF) Analysis of material flow and

2015年8月1日 The results show that approximately 2.48t, 4.69t, and 3.41t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages

Types of Cement Manufacturing Process [Explained in Detail]

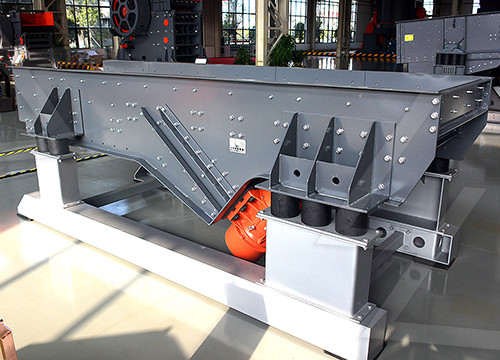

Stage 3: Raw meal drying, grinding, and homogenization. The raw blend, high evaluation limestone, sand, and iron metal are taken care of from their containers to raw factories, called air cleared plants, for drying and fine grinding. The raw plant contains two chambers, isolated by stomach, specifically a drying chamber and a grinding chamber.

Cement Manufacturing Process: 6 StepsTo Make

2020年1月27日 In the raw meal grinding production, the cement raw materials will be ground into finer size to make sure good mixing. In this stage, there are two types of the raw mill to choose, the vertical cement

Tiffany Huang on LinkedIn: #cement #production #line

#CEMENT #PRODUCTION #LINE #construction #technology Cement production line is the construction project to produce cement by a series of equipment. LVSSN group

Cement Making Plant Suppliers, Manufacturers,

Find Cement Making Plant Suppliers. Get latest factory price for Cement Making Plant. Request quotations and connect with international manufacturers and B2B suppliers of Cement Making Plant. Page 1

Jaypee Group Businesses Cement-Manufacturing Process

2021年9月15日 Limestone is extracted transversely from the stockpiles by the reclaimers and conveyed to the Raw Mill hoppers for grinding of raw meal. Crushing StackingReclaiming of Coal. The process of making cement clinker requires heat. Coal is used as the fuel for providing heat. Raw Coal received from the collieries is stored in a coal yard.

Distribution of Heavy Metals in Portland Cement

2023年3月8日 Composition of the raw-meal was prepared from raw-materials in the next ratio: limestone : fly ash : sand = 80,5 : 13,3 : 6,2 (wt. %), with addition of 250 t/day of coal as fuel. Regarding the composition of the raw meals, various cement standards (lime standard, silicate module, alumina standard) were considered.

How Cement Is Made Heidelberg Materials

2023年4月10日 The desired raw mix of crushed raw material and the additional components required for the type of cement, e.g. silica sand and iron ore, is prepared using metering devices. Roller grinding mills and ball mills grind the mixture to a fine powder at the same time as drying it, before it is conveyed to the raw meal silos for further

A Review on Pyroprocessing Techniques for

2020年2月9日 Vertical roller mills (VRMs) with integrated classifiers have been used successfully for many years in cement plants to grind and dry raw materials simultaneously with moisture contents up to 20% by weight.

I03 cement June 2010 GS-gct IEA-ETSAP

2022年4月11日 on drying the bulk materials to form a dry powdered meal. The choice of process depends on moisture content of the available raw material. When wet raw materials (moisture content over 20%) are available, the wet process can be preferred. However, in Europe, today’s new cement plants are all based on the dry process as the wet process

A STUDY ON THE CUSHIONING EFFECT OF CLAY ON

2019年9月13日 The normal flow sheet for cement production, either by dry or wet operations begins with crushing of the two main components. Either limestone or shale are crushed separately then, ground simultaneously as a mixture (80% limestone and 20% shale) in a ball mill. This procedure consumes

Dry Process Of Cement Manufacturing Dry Cement AGICO

After that, the raw meal will be completely calcinated into cement clinker in the cement kiln by high-temperature heating. Cement Kilns Manufactured By AGICO Cement kiln: the dry method cement kiln manufactured by AGICO has the characteristic of stable performance, low energy consumption, high yield, and easy operation. We equip our cement kiln

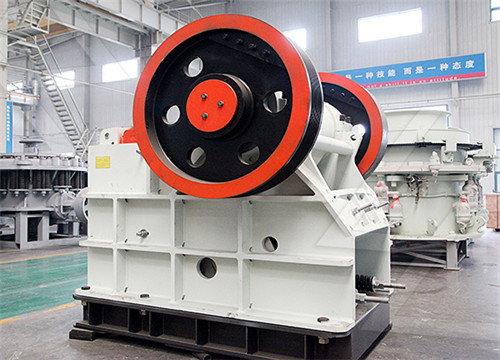

cement manufacturing Cement Plant Optimization

The raw material preparation comprises of the following operations: Crushing. Pre-Homogenization (Stockpiling) Raw material proportioning, drying and. grinding. Blending and kiln feed. Crushing. Crushing can be defined as comminution (size reduction) process to reduce the size of Run of mine (ROM) Limestone/sandstone to size (10-30mm

Characterization of a Marl-Type Cement Raw Meal as CO2

The use of poured raw meals as sorbent precursors for CO[2] capture can reinforce that synergies between the primer production process the calcium looping CO[2] capture technology. In this employment, we action an CO[2]

Tiffany Huang on LinkedIn: #cement #production #line

#CEMENT #PRODUCTION #LINE #construction #technology Cement production line is the construction project to produce cement by a series of equipment. LVSSN group

Cement Making Plant Suppliers, Manufacturers,

Find Cement Making Plant Suppliers. Get latest factory price for Cement Making Plant. Request quotations and connect with international manufacturers and B2B suppliers of Cement Making Plant. Page 1

Cement Extraction and processing Britannica

Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by excavators. The excavated materials are